With the level of technological advancement, you no longer need to manually monitor your water pump, to turn it on when your tank water goes down and to turn it off when the water tank is full. A simple automatic water control system, consisting of a contactor and a float switch can do the switching job perfectly and automatically. You will learn how to construct and install a simple and cheap water pump control system using a float switch and a contactor in this article.

How an Automatic Pump Control (APC) System Works

The principle of operation of an APC system is very simple. The two main devices that constitute this automatic pump control system are the float switch and a magnetic contactor switch.

Float Switch

A float switch is a mechanical type of level sensor device that is used to detect the level of liquid within a tank. It can also be used to control water pumps (as an indicator or an alarm) and can also be used to control other devices. Most common float switches make use of a reed switch mounted in a tube, which is submerged in a water tank. This reed switch consists of a float and a magnet, which are guided by the tube. The float switch has a 3-core cable, which is used to link it to a relay, or contactor switch in this case. Each core in the cable has a different colour; usually red (NO, which means Normally Open), blue (NC, which means Normally Closed) and black (which is the common).

In a low water level scenario, the water pump should be ON automatically (i.e. to start pumping water into the water tank). For this to work, the blue wire (NC) and black wire (Common) of the float switch should be connected to the circuit. This is because the circuit is completed in the normally closed condition.

What actually happens is that when the water in the tank drops to a certain level, the submerged part of the float switch slants downwards, causing the float to raise the magnet to the reed switch. This completes (closes) the water pump circuit and the pump starts pumping water into the water tank.

Also, in the high water level scenario, the water pump is expected to turn off automatically (i.e. to stop pumping water to the water tank). For this to work, the blue wire (NC) and black wire (Common) of the float switch should be connected to the circuit. This is because at this position, the circuit becomes incomplete in the normally open condition.

Here, what happens is that when the water in the tank rises to a certain level, the submerged part of the float switch slants upwards, causing the magnet to roll away from the reed switch. This opens the water pump circuit and the pump stops pumping water into the water tank.

Magnetic Contactor Switch

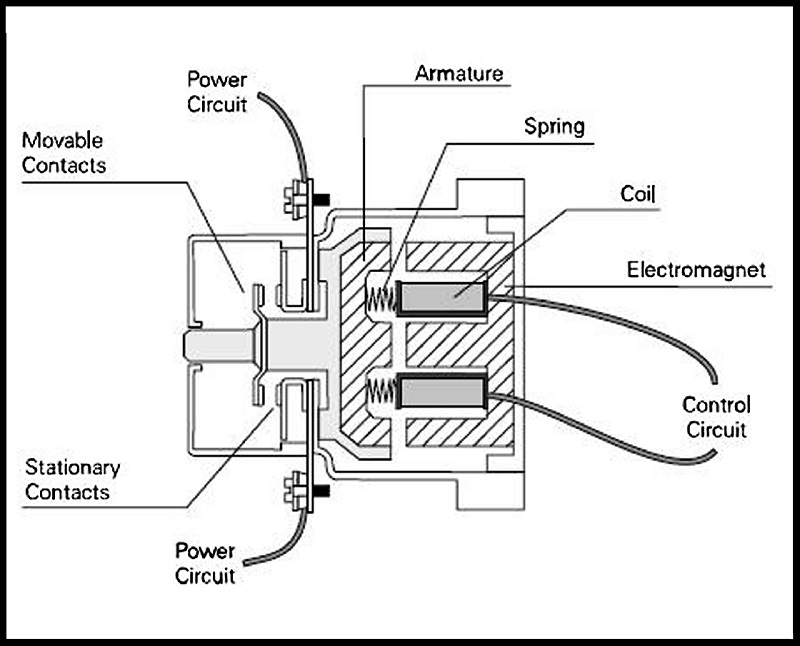

A magnetic contactor is an electrically controlled switching device that is used to make or break the connection between load and power supply. It is usually used in electric motor control applications and does the work of relays. When electric voltage is applied to the coil from the control circuit, it energized the electromagnet, thus creating a magnetic field. This magnetic field then pulls the armature towards the electromagnet, thus closing the contacts. Once this happens, the circuit becomes complete (closed), therefore current flows through the power circuit from the line to the load.

Note that the side labeled L1, L2 and L3 is the line input side of the contactor, which will link the contactor to the mains. The side labeled T1, T2, T3 is the output side of the contactor, which will link the contactor to the load. A1 and A2 are the auxiliary contacts points that connect power to the magnetic coil. These are where the terminals of control units are connected.

Working Principle of an Automatic Pump On/Off System

The float switch floats according to the water level in the tank. When the water tank is full, the float switch floats in a horizontal direction. At this position, the sensor in the float switch sends signal to the contactor, so it switches and opens the circuit. As a result, the water pump turns off. But as the water level goes down, the float switch tilts downwards, until it is completely in a vertical direction. At this position, the sensor in the float switch sends signal to the contactor, so it switches and completes or closes the circuit. As a result, the water pump turns on and water starts entering into the tank. So the float switch ensures that the water level in the tank does not go below a certain low level and also does not go above a certain high level. You need to manually adjust the position of the float tank and indicate these two critical water levels.

Check:

- Overview of 5G: Protocols and Standards, Benefits and Challenges

- Facial Recognition Technology & How to Use it for Business Adverts

How to Know the Rating of Contactor Switch to Use

The rating of your load (in this case, the water pump) will determine the rating of contactor switch to use. Water pumps are usually rated in electrical horsepower (hp). But contactors are usually rated in Ampere (A). So we will do a little calculation to determine the rating of the water pump in Ampere.

1 electrical horsepower (hp) = 746 Watt (W)

Recall that electric Power, P = Current (I) x Voltage (V)

Voltage referred here is the value of single phase voltage, which is 230 V in Nigeria and 120 V in USA. Phase voltage value differs country by country. For most countries, it is 230 V. You can check the single-phase voltage of your country here.

Making Current (I) the subject of the formula;

Current (I) = Electric Power (P) / Voltage (V) = P/V

Therefore the Current (I) rating of your water pump, whose horsepower rating is known is calculated as:

= (746 x Power rating of the water pump in Horse Power) / Single phase voltage

For example, if the horsepower rating of your water pump is 1 hp and you reside in a country whose single-phase voltage is 230V, the current (I) rating of your water pump will be

= (746 x 1) / 230 = 3.24 A

Therefore, you need a contactor switch that is at least equal to the rated current of the water pump. You should also consider the small current drawn by float switch. Most float switches take maximum voltage of 265V, maximum current of 1A and consume a maximum of 50W power.

Also you need to know the full load current of the pump. So, in real life, you will need a contactor switch with the current rating of about 4A to 5A for a 1hp water pump using a single-phase voltage.

NOTE:

There were many assumptions made in this calculations. We didn’t consider the actual values of some parameters like: the efficiency of the pump, power factor,

All these parameters and formulas for calculating the full load current of any electric motor, which uses either a single-phase voltage or 3 phase voltage are explained in details in the screenshot below.

If you hate calculation or find the formula a bit confusing, then make use of this horsepower to amps calculator.

How to Install the Automatic Pump Controller: Simplified DIY Guide

- Make sure you have switched off the mains to avoid electric shock or damage to any of the components. You can do that by switching off the control switch of your distribution box.

- First, fix the float switch in the water tank, making sure the sensor touches your desired low water level when in the vertical position. Also make sure that your chosen high water level will not make the water tank to over full.

- Next, connect the phase wire (red) and neutral wire (blue or black) coming from your distribution box to points labeled L1 and L2 respectively. Then from point L1, loop a red wire to point A1 on the contactor. Also from point L2, loop a black wire to the black cable of the float switch. Since we are using single phase voltage, there will be no connection on points L3 and T3.

- Now, with wires of the same type and diameter as those used for connecting the input side of the contactor, do similar connection for points T1 and T2 as you did for points L1 and L2. Take note of where you connected the phase and neutral wires for the input side of the contactor and follow the same sequence for points T1 and T2. Phase wire (red) should be connected to point T1, while the neutral wire goes into point T2.

- Next, use a blue wire to make a connection from point A2 on the contactor to the blue cable of the float switch.

- Congrats! You have successfully installed an automatic pump controller. Switch your distribution box control switch on. Your pump should be and start pumping water into your water tank. Once the tank is full, the pump will automatically go off.

- Optionally, you can connect an indicator which will glow when the water tank is full. To achieve this, connect a red cable and a black cable to the two terminals of a lamp holder. Next, connect the red (NO) cable of the float switch to the red cable from the lamp holder. Then tap from the neutral cable from the mains (the one connected to L2) and connect it to the black cable of the lamp holder. An alarm switch can also do the job.

The screenshot below summarizes all the connections explained above.

You can get a quality float switch from ebay here. For a contactor, check here.

NOTE: This automatic pump control system can control any number of tanks. All you need to do is to ensure that the tanks are connected in series. With that done, you can fix the float switch in one tank and it takes care of the rest. This is just one of the ways to automatically control your water pump. You can also build an automatic water level controller circuit by yourself.

Video of How to Install an Automatic Pump Control On/Off System

See:

- The Domestic Uses of Flow Control Valves Regulators

- How to Choose the Best Solar Batteries & Panels for your System

Conclusion

You have learnt how an automatic pump controller works with the aid of a float switch and a contactor, how to choose the correct contactor rating for any water pump rating, how to do the connection and installation.

Did you find any section of this article confusing? Comment your question in the comment section below. Share this article with your social media friends by clicking a share button. Don’t forget to subscribe via email to stay up to date with our DIY tutorial articles. Enjoy!